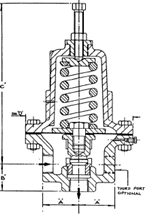

The type R730 Diaphragm Relief Regulator maintains a constant inlet pressure and will protect a system against pressure surges. This valve can be installed for angled flow with bottom port as outlet, or it can be supplied with a third port in line for straight through flow, (high viscosity applications) still using bottom port as outlet. Variations from standard valve include special materials to customer’s requirement and ‘T’ bar hand adjustment.

Operation

The pressure to be controlled exerts force under the diaphragm. When this pressure level set by the pressure spring is exceeded the diaphragm moves upwards opening the plug to which it is attached allowing excess fluid to pass out of the bottom port. As soon as sufficient fluid has been bypassed to restore the pressure to the required level the pressure spring closes the plug. The valve plug is continuously positioned to maintain the required pressure.

Specifications

BODY SIZES

½”, 3/4″, 1″, 1½”

BODY CONNECTIONS

Screwed NPT OR BSP

BODY MATERIALS

St/steel, carbon steel.

SPRING CHAMBER

Steel, St/Steel

DIAPHRAGM

St/steel, elastomers

TRIM MATERIALS

St/steel

CONTROLLED PRESSURE

0.7 – 14.6 BarG – ½” – 1 Valves

0.9 – 11.3 BarG – 1½” valve

MAX OP. TEMPERATURES

200ºC St/Steel diaphragms – 85ºC Nitrile diaphragms

MAX BODY RATING

18 BarG – frac12;” – 1″ valves 13.8 BarG 1½” valve/